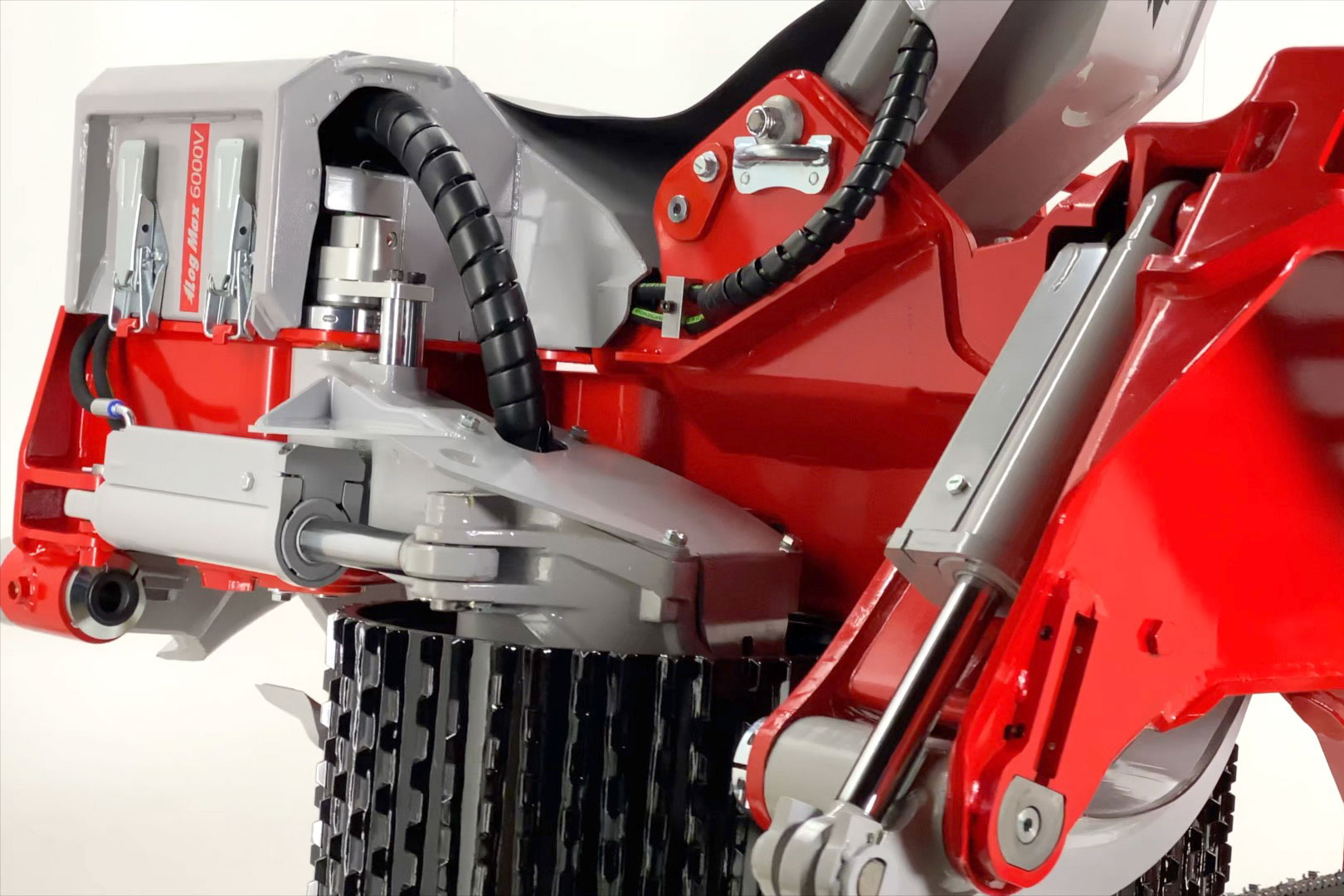

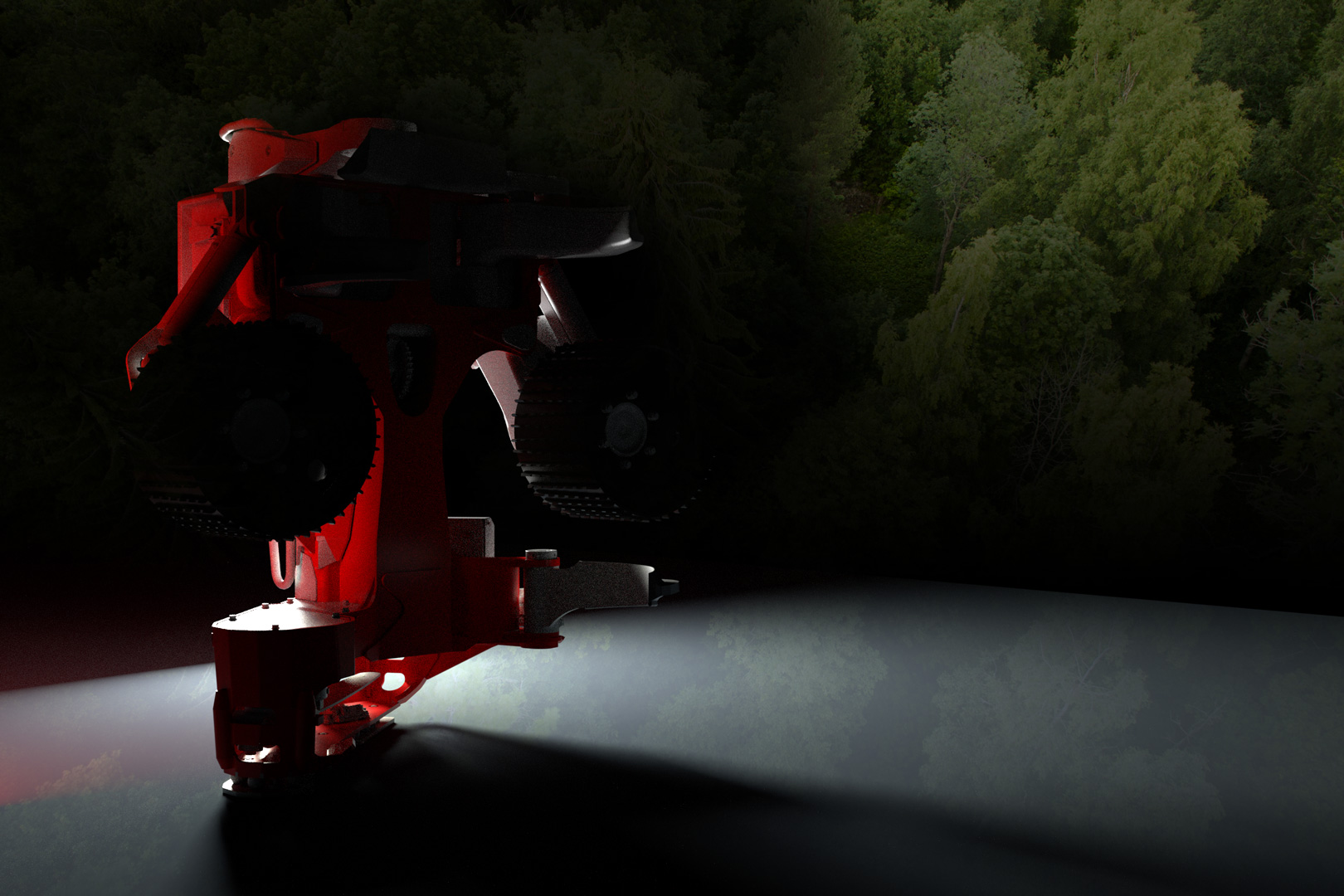

Log Max 6000V is a versatile head, which has a wide range of applications, mainly focused on final-cut. The head is powerful and fast with excellent length measurement results.

PRECISE MEASURING

Updated length measurement function to offer the best possible measurement results.

FAST SAW

Can be equipped with our smartest saw True-Cut 218 and 318 for fast and trouble-free cutting.

EASY SERVICE

The head is built to simplify and facilitate service and maintenance for the driver.

Weight

1342 KG

Highest productivity

14 - 44 CM

Between feed rollers

1.5 - 62.5 CM

Max cutting diameter

71 CM

Assets diameter

46.6 CM

What do customers say?

Alex Pickard, New Brunswick, Canada

The 6000V is an amazing head! Super fast, very reliable and lengths and diameters are always 100%. Feeds the trees very smooth and takes all limbs off. The Log Max team is a very smart team and have minimal down time with any issues as they help fix over the phone. Highly recommend the head!

Petri Ylinen, Sweden

It's unbelievable! I have previously had problems with measurement on Log Max head, but now our numbers are enormously high. We are between 96-97%, and that means that the new measuring update works perfectly! I want it to be clear that I have these numbers. I know that it is essential for the forestry industry companies that the measurement works well, and it does that now! It takes all limbs off well and feeds well, but above all, it measures well.

FEATURES

What makes Log Max 6000V your best choice

Improved length measurement

To offer the best measurement results, we’ve made some changes in the length measurement function.

We have updated the construction of the measuring wheel cylinder, the hydraulic circuit and reinforced the measuring wheel arm and its attachment.

We also have a completely new measuring wheel unit including a bigger measuring wheel. Altogether, the changes will allow the measuring wheel to follow the contour of the stem even better and provide the best measurement result.

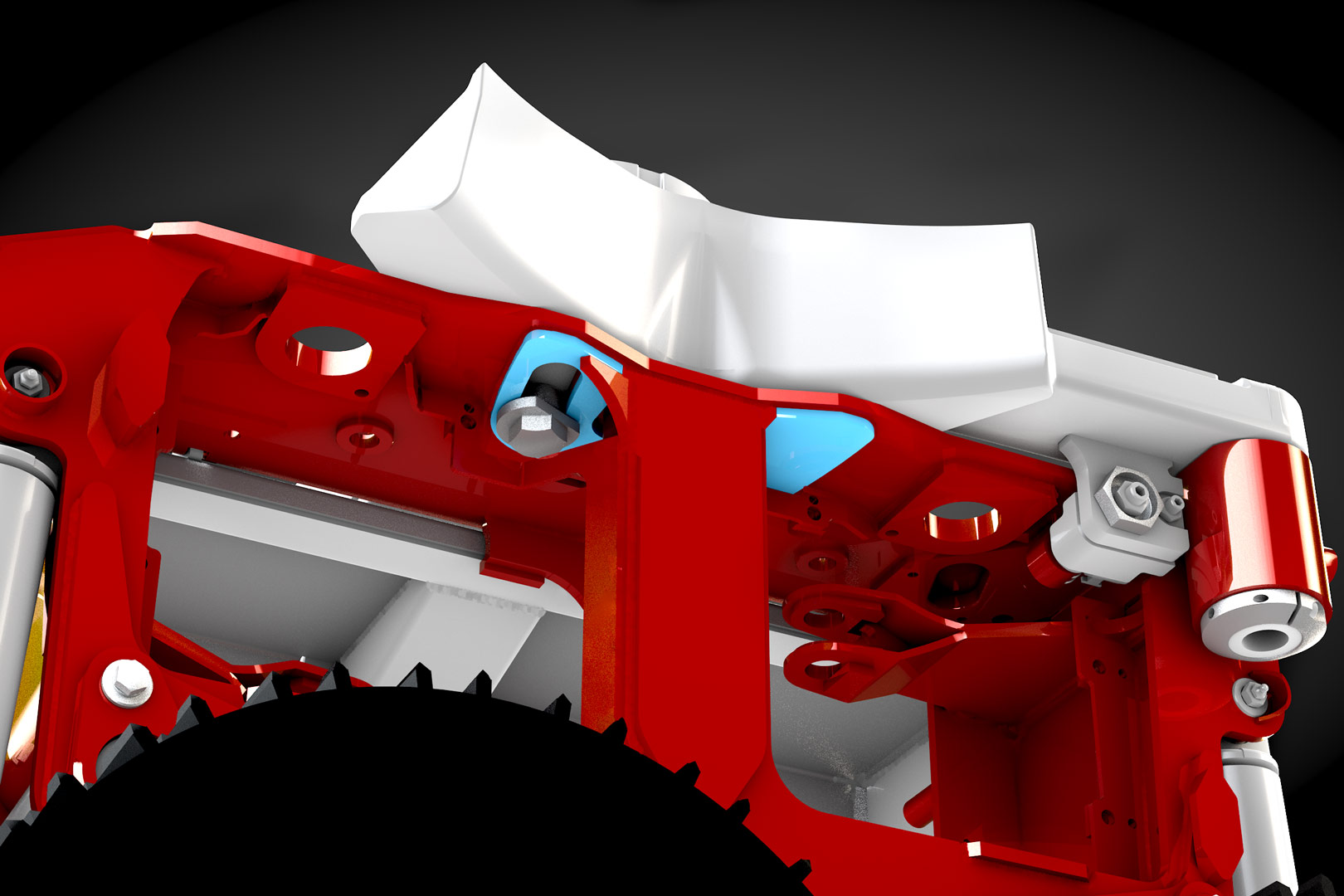

Reinforced frame

To increase durability and reduce the risk of cracks in the frame, we have created a reinforced attachment for the upper delimbing knife.

The frame is reinforced at the mainline, where the upper delimbing knife slides on the frame to increase durability and extend its life span.

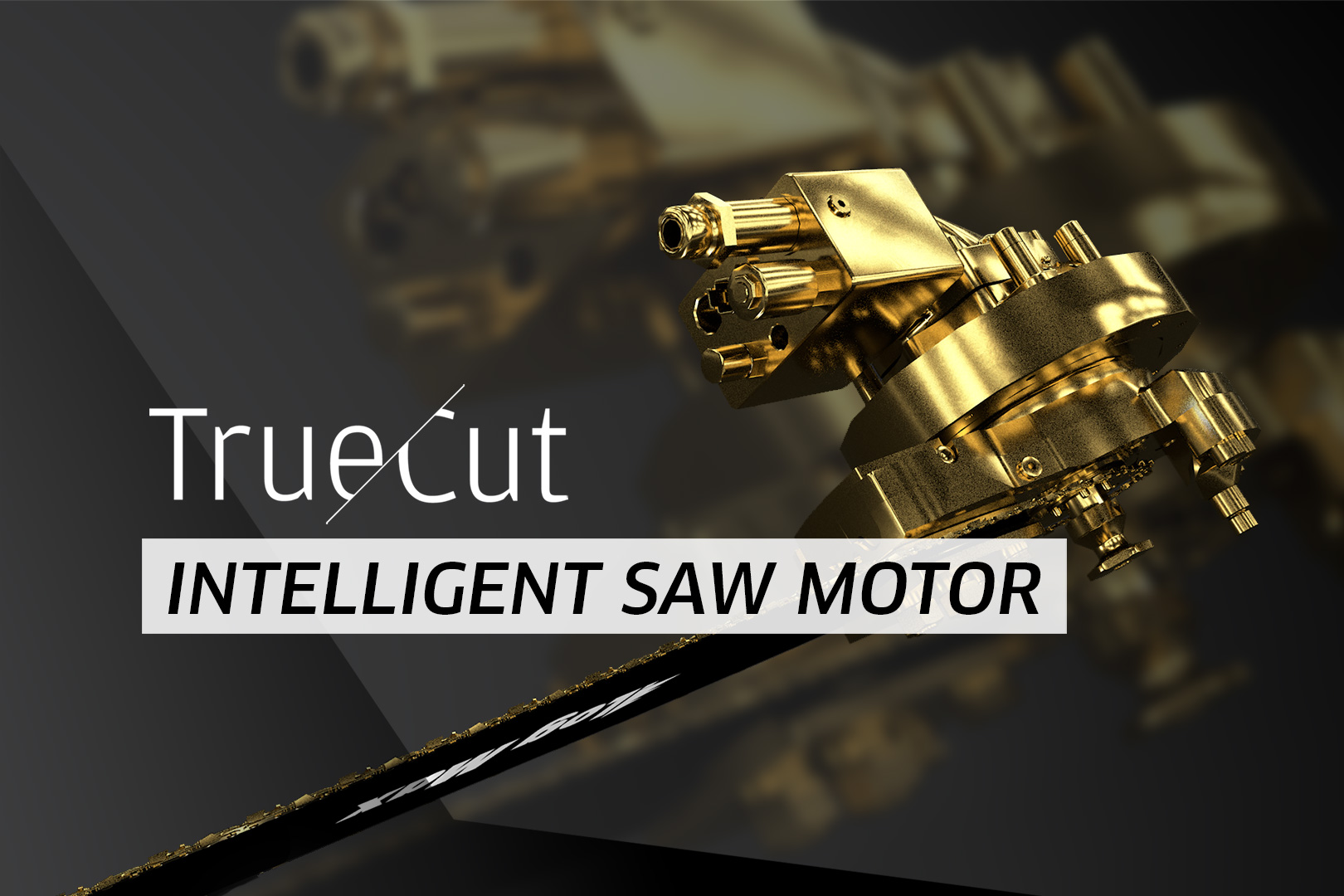

An impressive saw unit

True-Cut is our smartest and fastest saw and we recommend you choose True-cut 318 that features automatic chain tensioning.

The integrated valving solution continuously senses the motor speed and adjusts the saw bar accordingly, the True-Cut maintains an almost constant chain speed of 40 m/s throughout the cutting cycle. The True-Cut is optimized at the factory and should not need any further setting changes in the field. For True-Cut to work, a minimum flow of 200l/min and a minimum pressure of 250 bar is required.

Read more about saw units

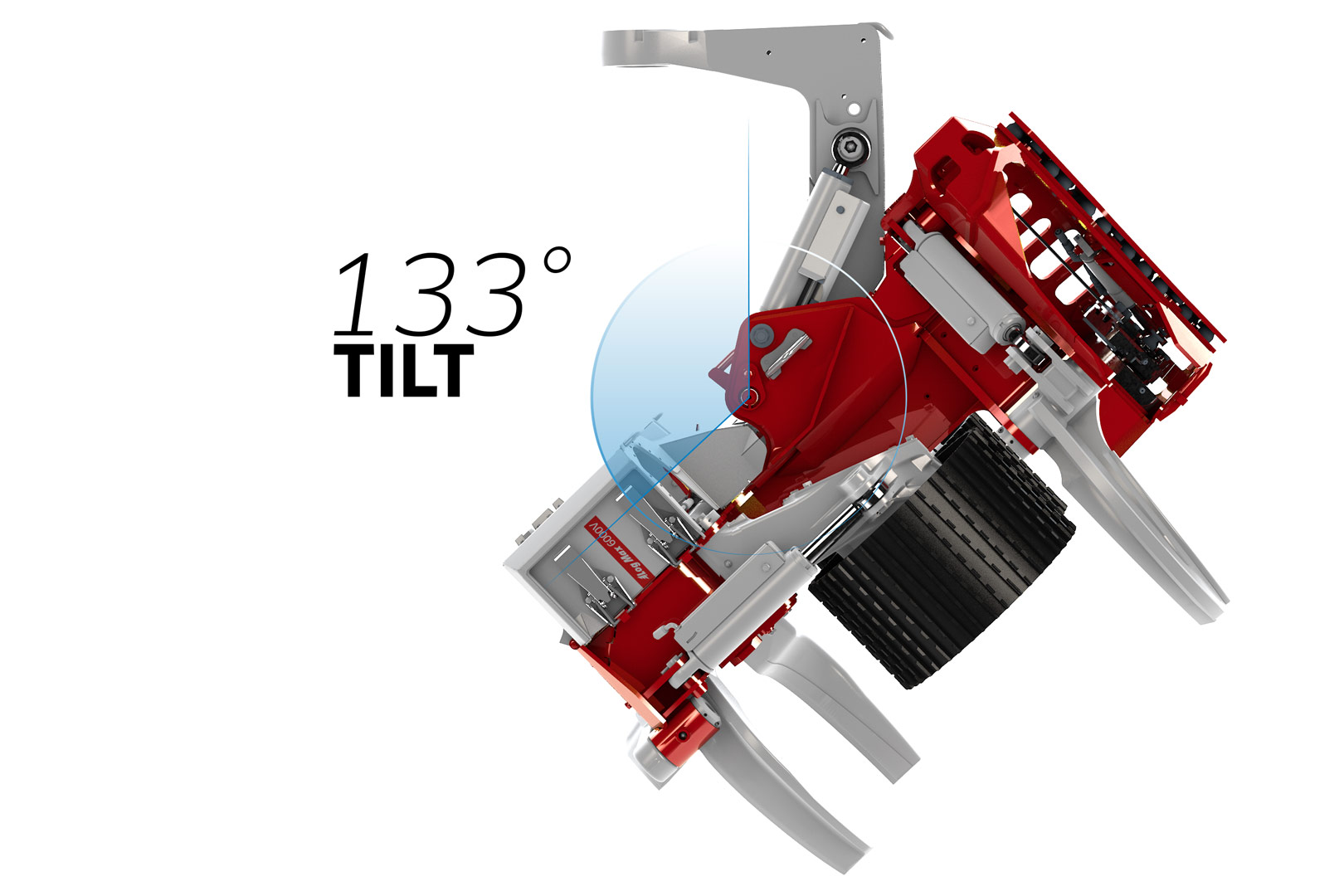

Increased tilt angle

The head has a new, increased tilt angle of 5°. The change gives the head greater mobility, which is always an advantage. It will also make it easier for the operators who work with the head on steep slopes.

Stronger cylinder

The delimbing knife cylinder has been updated. The new cylinder has stronger attachments against the frame and knife. The update results in better durability and extended life span of the cylinder.

Reinforced around measuring wheel

To improve the frame’s durability and life span, we have changed the design of the measuring wheel hole. We also reinforced the stoppers for the roller arms, when in the closed position, at the inside of the frame to increase the frame’s strength and stability.

Replaceable pins for felling link cylinder

The pins for attaching the felling link cylinder in the frame are screwed at both ends. The refinement will simplify service and maintenance.

Easier access

Updated attachment for the expander pin to measuring

wheel arm to simplifying service and maintenance.

TECHNOLOGY

Unique technologies for your Log Max head

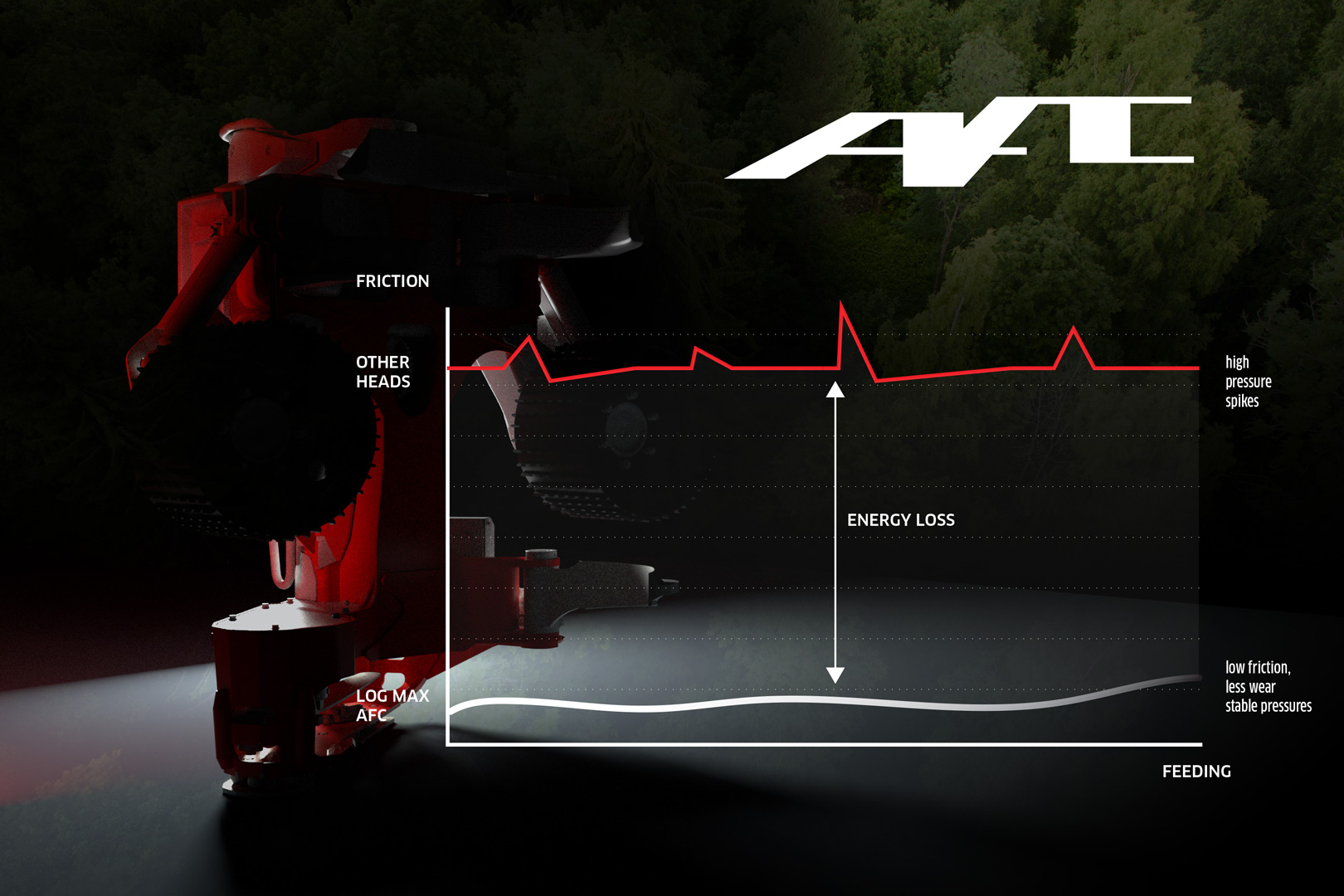

Active Friction Control - AFC

The AFC system is our heads' key technology and allows our heads to harvest trees with high precision and minimal friction.

The goal of the AFC is to minimize the friction between the trunk and the frame, which leads to minimal wear on the unit and lower operating costs because the head doesn't use more power than necessary.

The wood quality will also be high, as neither knives nor feed wheels need to use unnecessary force that damages the wood during processing.

Read more about AFC

Log Mate 510

Log Mate 510 is our control system which is specially developed for Log Max harvester heads and is the absolute best control system for our products.

The control system is robust and compact and of the highest quality.

It is Windows-based, which simplifies the administration and updating of the system and provides good support for all new programs and services. The system uses the latest forest standard StanForD 2010 v2 and v3 and consists of three modules, screen, cabin, and head module.

Learn more about Log Mate

Eucalyptus harvesting

Log Max heads can be equiped with eucalyptus feed rollers. These feed rollers have been developed to remove the thick bark from the stems during processing optimally.

The head has five delimbing knives for optimal stem holding and easier barking of the stems.

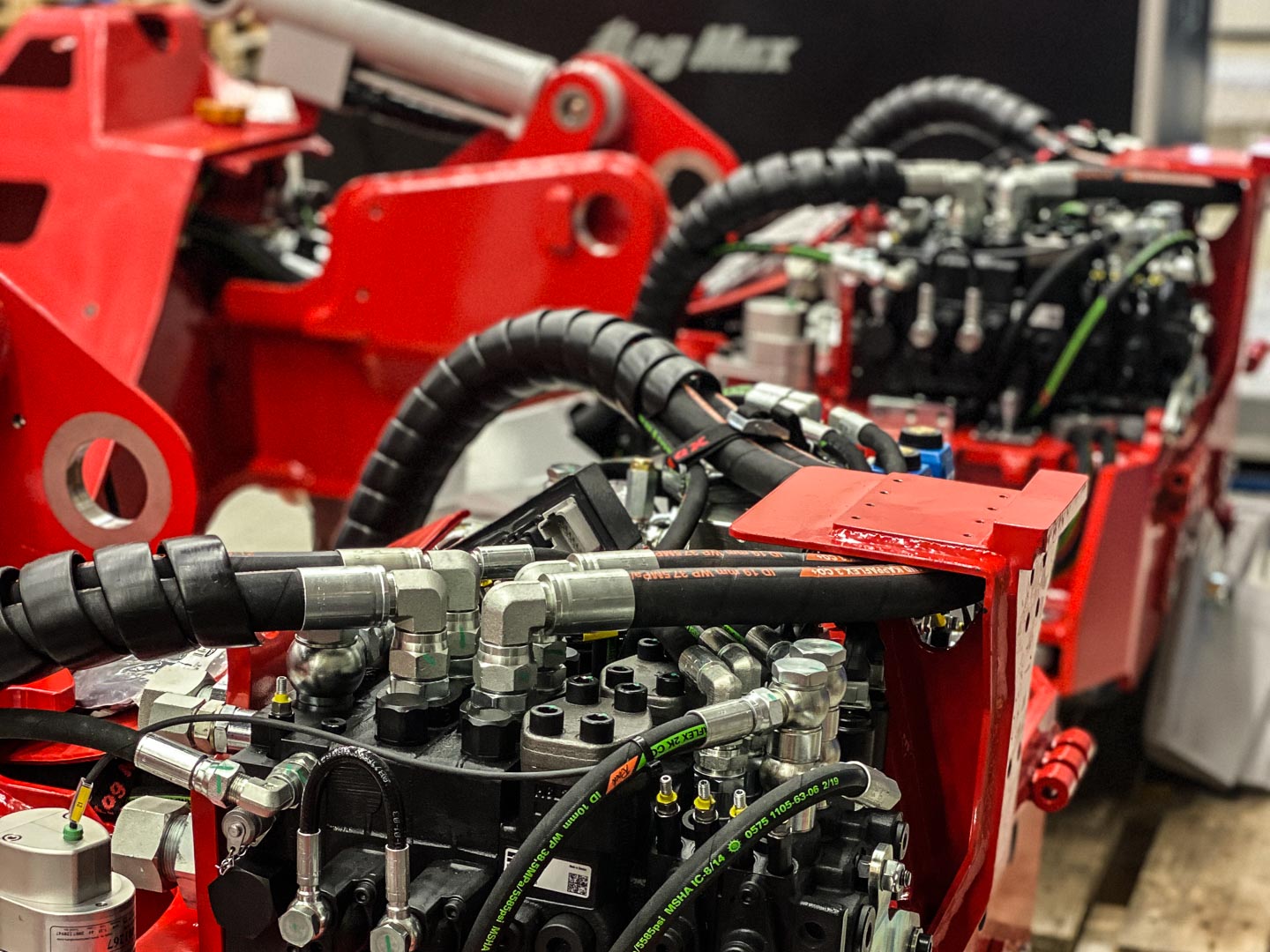

Hydraulics

The hydraulics of our heads are characterized by a simple design. We use a proven technology that we trust and that results in reliable hose management and stable pressures throughout.

Our system has small hydraulic losses, which means that we get the most out of the head's performance.

More about the head design

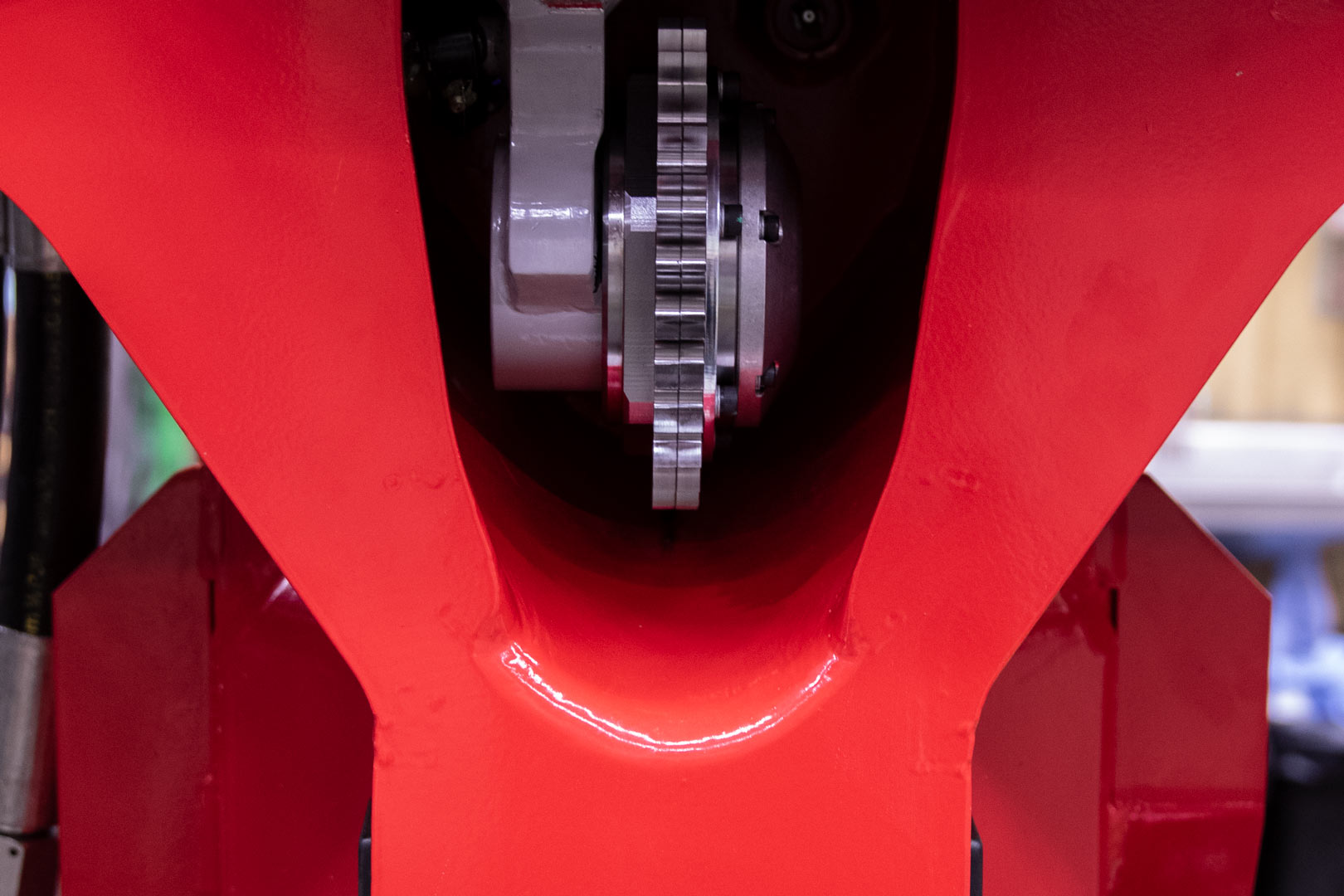

Feed rollers

To optimize the head's function, you need to choose the feed rollers that fit both your head, but also the type of forest that you work in the most. Our feed rollers always work perpendicular to the tree, in contrast to many other units that have angled feed rollers. Having a straight feed roller leads above all to reduced friction losses but also to minimal penetration into the trunk.

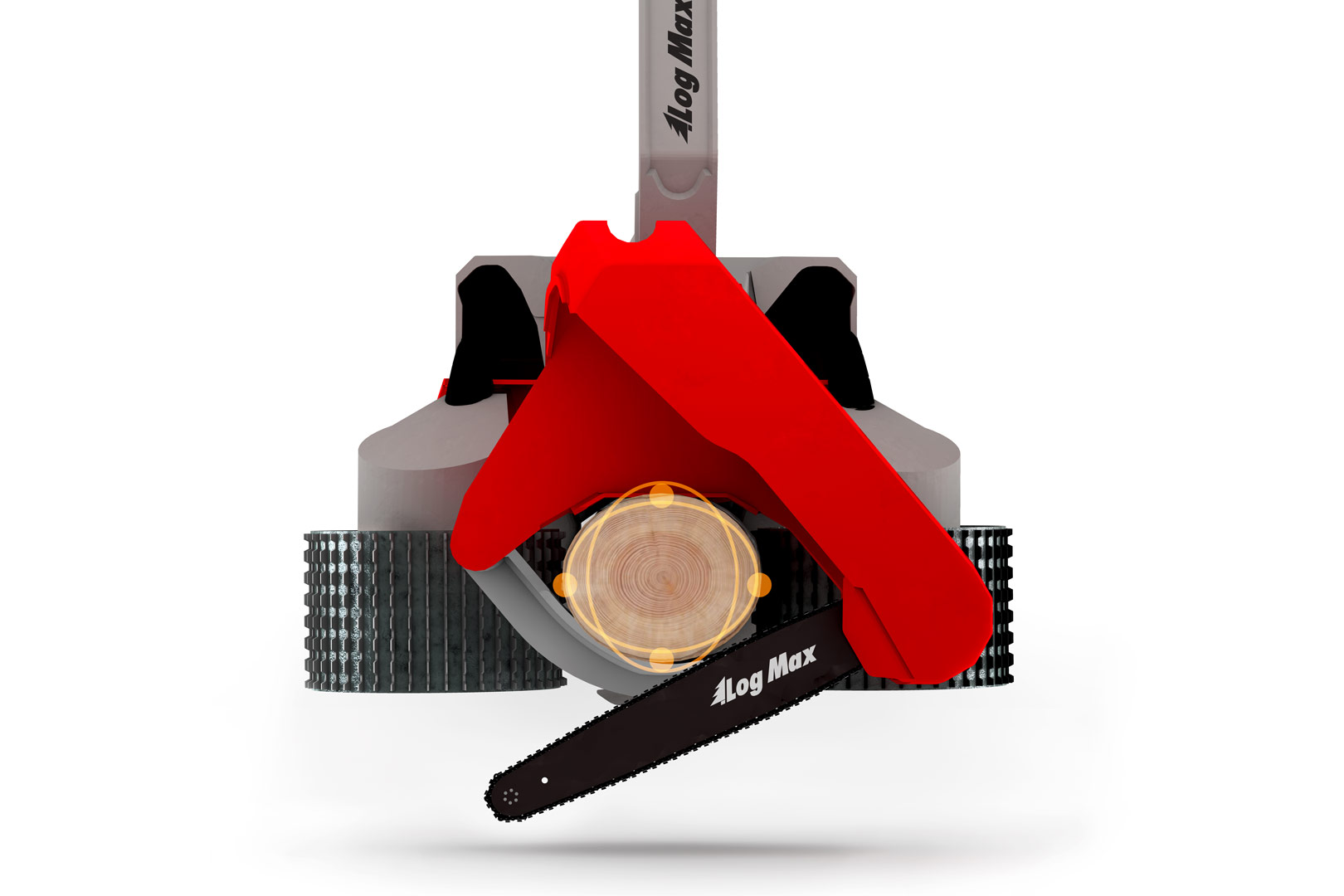

4 point measurement

The four-point measurement results in both a good volume calculation and accommodation. The measurement is made in four points, two opposite points each other in the feed rollers, one point in the lower delimbing knife (via a sensor), and a zero point on the frame.

Learn more

Multi-stemming

In order to be able to harvest several trees at a time and thus streamline the work, Log Max harvesting heads (3000, 4000, 5000, and 6000 series) can be equipped with our

multi-stemming unit. A head equipped with a multi-stemming unit gets increased flexibility and can be used in several types of felling.

Learn more

EQUIPMENT

All optional equipment available for Log Max 6000V can be found here

Feed rollers for Log Max 6000V

V-STEEL SOFT GRIP

Self-cleaning feed wheels with high traction, both forwards and backwards, without risk of slip damage. The Soft Grip has a slightly lower stud (ca 5 mm) which gives less penetration into the trunk.

V-STEEL HARD GRIP

Self-cleaning feed wheels with high traction, both forwards and backwards, without the risk of spinning. The Hard Grip has a slightly higher stud (ca 10 mm) that provides a better grip around the trunk.

Eucalyptus

Log Max Eucalyptus feed roller is different from our other feed rollers. They are specially designed to debark the thick bark of eucalyptus trees.

Feed roller motors for Log Max 6000V

857 cc

Feed force: 28.7 kN

Feed speed: 5 m/s / 16.40 ft/s

934 cc

At 280 bar and 330 l/min the motors give the theoretic force:

Feed force: 31.3 kN

Feed speed: 4.6 m/s / 15.09 ft/s

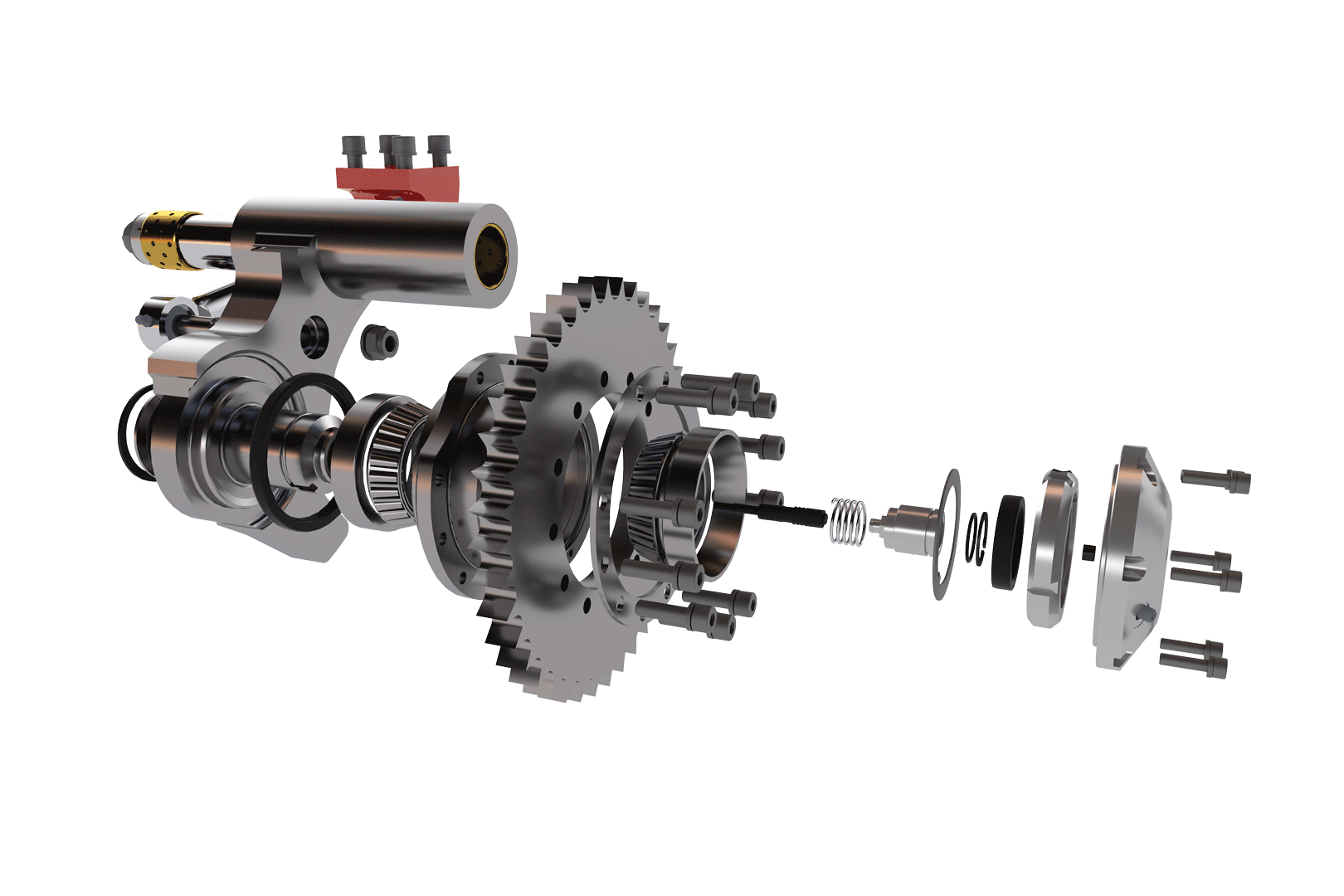

Saw units for Log Max 6000V

True-Cut, a really good saw

The True-Cut saw units have a built-in saw valve that senses the motor's speed and adjusts the bar feed speed to maintain a constant chain speed of 40m / s throughout the cutting regardless of tree species or diameter.

Read more

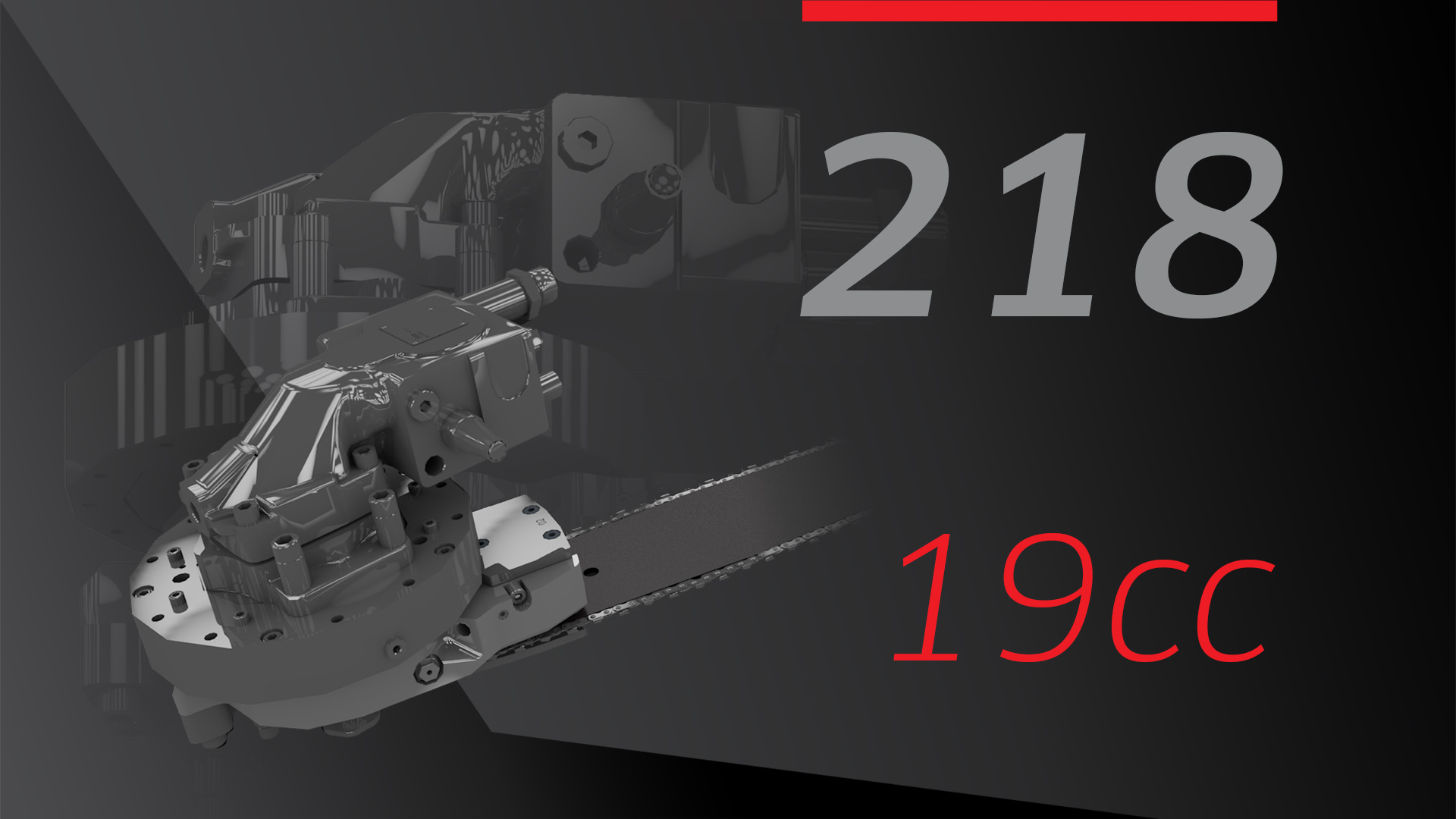

True-Cut 218 - 19cc

The True-cut saw units have a built-in saw valve that detects the motor speed and adjusts the saw bar feed rate according to the speed. This function allows True-cut to maintain a constant chain speed of 40m/s throughout the cutting, regardless of the tree size or species.

Tensioner: Manual

Saw Motor: 19 cc / 1.16 cu in

Saw Chain: 0.404"

True-Cut 318 - 19cc

The True-cut saw units have a built-in saw valve that detects the motor speed and adjusts the saw bar feed rate according to the speed. This function allows True-cut to maintain a constant chain speed of 40 m/s throughout the cutting, regardless of the tree size or species.

Tensioner: Automatic

Saw Motor: 19 cc / 1.16 cu in

Saw Chain: 0.404"

Saw 318 - 19cc

The saw 318 auto-releases the chain tensioner's pressure when you turn off the base machine, so you do not need any tools to change the chain.

Tensioner: Automatic

Saw Motor: 19 cc / 1.16 cu in

Saw Chain: 0.404"

Saw 318 - 30cc

The saw 318 auto-releases the chain tensioner's pressure when you turn off the base machine, so you do not need any tools to change the chain.

Tensioner: Automatic

Saw Motor: 30 cc / 1.83 cu in

Saw Chain: 0.404"

Rotators for Log Max 6000V

Indexator AV17S

The rotator has low weight and high performance. This is the perfect rotator for heavy lifting and hard work.

- 160 kN lifting capacity

- Robust and construction

- High torque

Indexator H182

Durable, powerful, and with the highest performance.

- 160 kN lifting capacity

- Optimized productivity and efficiency when combined with MPB swing dampers

- High torque and precise

Indexator HX 30

Low-profile HX is loaded with a number of advantages where the machine, driver, and unit work efficiently - quickly and smoothly.

- 160 kN lifting capacity

- Upper interface MPB2 184 mm

- Lower interface Ø 173 mm

SOMETHING EXTRA

Selectable optional equipment for Log Max 6000V

Processing knives

The processor knives have protruding tips that ease the prehension of logs from a pile of already felled trees. The processor knives are available in two designs, a welded and a cast one. They are equally durable but the welded one has replaceable knives edges, it also weighs slightly more.

Cylinder rod protection

Protects the feed roller arm cylinders on the unit. The protection is standard on all XT units, although we do recommend it for all units, especially when thinning where the head is more exposed to hits as the forest is often denser or working with hardwood.

Field repair kit

A spare parts kit with the most vital components to minimize downtime. Contains sensors, cylinders etc. The kit varies (content and price) depending on the head model and equipment.

Please contact us for more information.

Protective bar

The protection is mounted on the felling link to protect the crane hoses, multi-stemming hoses, and color marking tanks. Available in two versions for units with or without color marking.

Fixed bottom plate

Used instead of the damped bottom plate. An advantage when minimal stump height is needed.

Dust & Snow cover

This rubber cover is mounted between the felling link and the rear of the frame. This prevents snow and debris from packing that could damage the protective cover.

Sawdust deflector

To minimize sawdust clouds when processing a log and also the risk of chain shots, a sawdust deflector is mounted on the saw box.

Hose Kit

Kit with replacement hose.

Ask your local dealer for more information.

Color marking

Includes tanks and equipment for two different colors. Color marking blocks are mounted in the saw box.

Find End sensor - laser

Used to easily find the root end / zero point of a log. The Find End sensor consists of a laser that is mounted in the saw box. This allows to easily

zero-reset without having to use the saw. This function optimizes and facilitates work when processing from the pile.

Stump treatment

Prepares the head for stump treatment. Requires a separate pump on the carrier.

Rotator control

To reduce weight and cost, it is possible to choose the rotator control option, which means that the rotator is controlled from the head instead of from the carrier.

The advantages are that it frees weight on the carrier by eliminating between 20-30 m of hose and also reduces costs. If the option is chosen, an extra valve is mounted to the head.

Real Easy

Quick attachment to the rotator so you can easily mount and dismount the head.

Grease Lubrication

Prepares the unit for grease-based chain lubrication, an alternative to Easy Greasy. Requires a separate pump on the carrier.

XT-kit

You can equip your head with an XT kit to withstand the toughest working conditions. The XT-kit comprises a cast, extra-strong felling link, a reinforced protective plate, and our Heavy Duty kit.

Heavy Duty-kit

Mounted for increased durability and as extra protection for your head. The Heavy Duty-kit contains a reinforced felling link and extra protection for cylinders and feed roller motors.

Cast felling link

The felling link is cast in one piece to maximize strength and durability. The cast felling link is standard on all XT, TWIN and E6 heads. It is our most robust felling link, a must-have for tracked carriers.

Reinforced felling link

To increase stability and durability, you can extra equip your unit with a reinforced felling link. It is recommended when mounting the head on an excavator or for tougher conditions such as logging hardwood.

Multi-stemming

The accumulation kit is a good choice for you that wants to harvest several trees in every felling and thus streamline the work.

SUPPORT

Here you will find important information, links and contacts for the best support for your Log Max head.